Ph: 1800 822 220

Ph: 1800 822 220

How to Choose an Inline Filter for Your Compressed Air System?

Why do you need a filter(s) for compressed air?

Picking out an inline filter is not an art, but it could be confusing if we do not ask the right questions or understand the process that requires filtration. Before we move any further, let’s take a step back and get a general idea of filtration and why it plays an important role within the compressed air system.

Why do you need a filter?

When you have a taste for coffee, it is simple to go to your nearest coffee bar or use a popular ‘cup’ machine, but we want more. The example I’d like to use consists of using the drip coffeemaker and roasted beans. One of the most important items in making a good cup of coffee in such machine is to use a proper filter in order to avoid a cup full of grainy particles and any other remaining pieces of the coffee bean. As insignificant as it might seem, the paper filter plays a vital role in making coffee that you can enjoy.

Although, a different entity than a coffeemaker, your compressed air system needs a filter as well. Compressed air is full of particles, aerosols and oil vapours (in oil injected pistons and screws) that contaminate the compressed air and can cause potential harm to its end users (equipment that uses compressed air). Incorporating the correct inline filter can help you eliminate the unwanted particulates as well as aerosols and vapours.

The amount of filters and types needed will be dependent on the quality of air your application and or process requires. Let’s take a look at the different types of filters and the questions that will help you choose the correct filter.

Downloads - air quality guide

High Quality Compressed Air for Your Process

ISO-8573:2010 Part 1: Contaminants and purity classes

Vital Importance of Compressed Air Quality

The quality of compressed air used in industrial processes is specified in the International ISO 8573 standards.

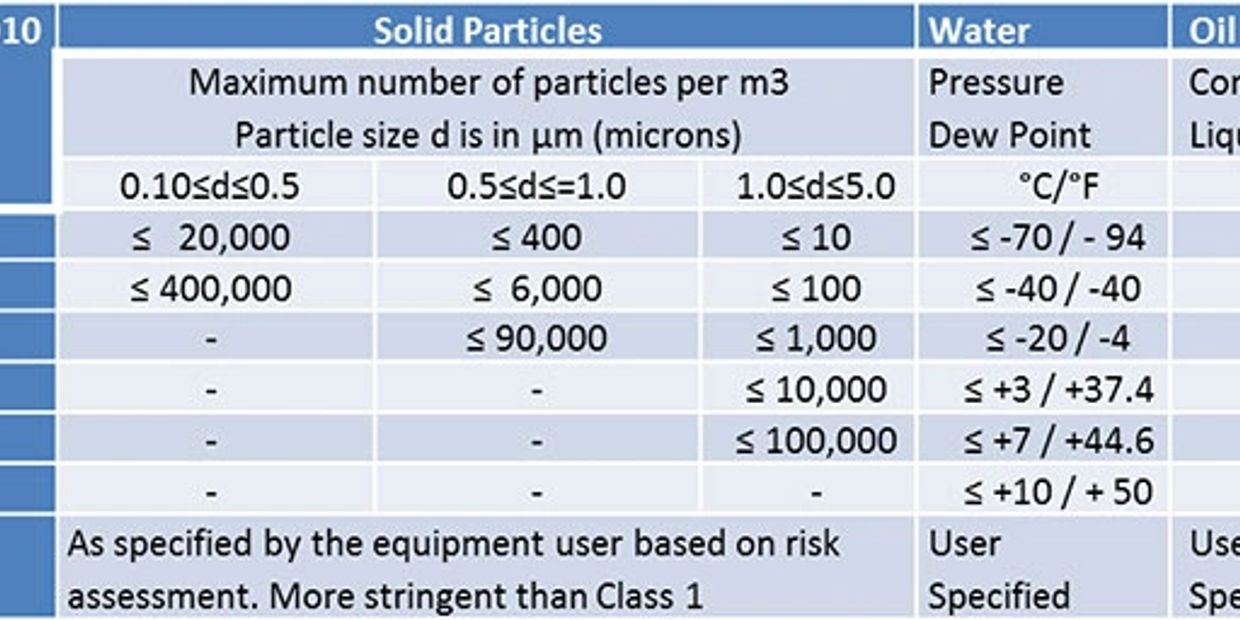

ISO 8573-1:2010 specifies and defines purity classes of compressed air with respect to particles, water and oil.

ISO 8573-1:2010 also provides general information about possible contaminants in compressed-air systems as well as links to the other parts of ISO 8573, and includes the measurement of compressed air purity and the specification of compressed-air purity requirements.

If you use compressed air in your manufacturing process it is vital that the quality of compressed air used in your process is in accordance with the required quality class to prevent risk to product quality, human health and corporate reputation.

ISO 8573:2010 Explanation

Of the separate parts in the standard, ISO 8573-1:2001 part 1 relates to defining the quality of compressed air used in different applications. The other parts are concerned with the methods to test the air for a range of parameters used to indicate the level of contamination.

ISO 8573-1 specifies purity classes of compressed air in respect of particles, water and oil. The purity classes can be used to describe the current quality of a compressed air system or to specify the required quality for a precise application.

Quality Classes according to ISO 8573-1 are summarised in the following table:

CPS Compressors Australia

Air Compressor Sales, Service of all brands, Spare Parts, 24/7 Breakdown - Unit 28, 20 Tucks Road, Seven Hills, Sydney, NSW 2147, Australia

Copyright © 2025 CPS Compressors - All Rights Reserved. Authorised DENAIR Distributors

Part of the CPS Group of companies, Australia