Ph: 1800 822 220

Ph: 1800 822 220

Nitrogen generated on site for food & beverage production

FOOD AND BEVERAGE

Nitrogen - On Site Generation

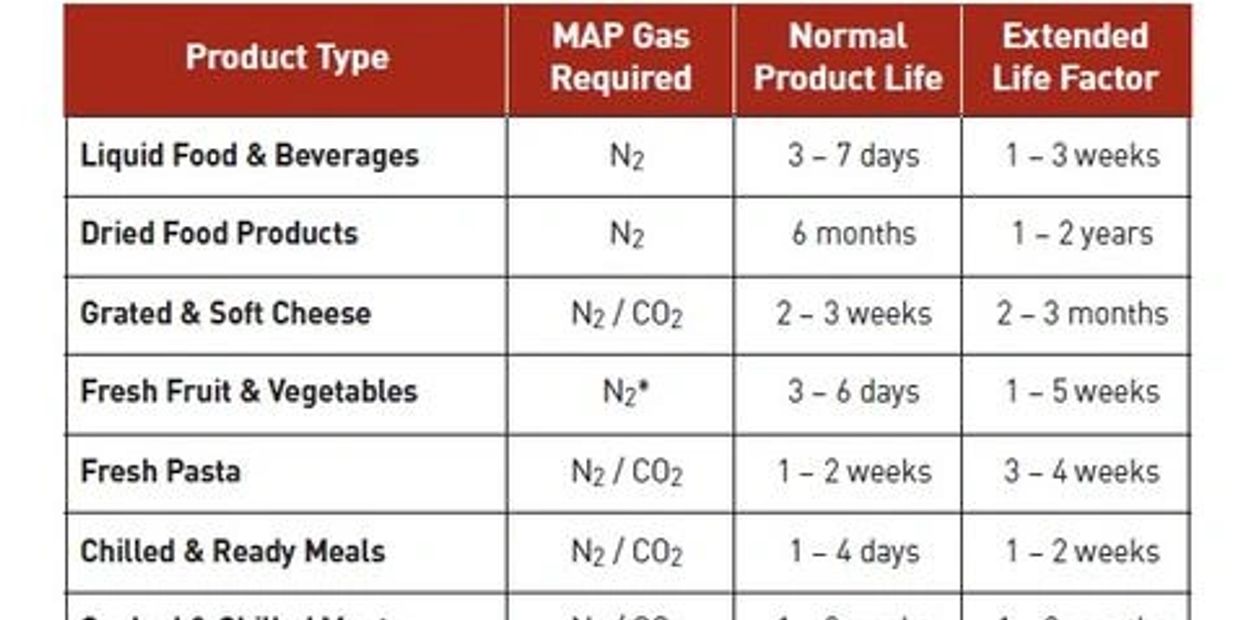

Modified atmosphere packaging

Modified atmosphere packaging (MAP) is food packaging in which the composition of the air surrounding the food in the package is changed. The main gases used in MAP are oxygen, carbon dioxide or the inert gas, nitrogen.

The MAP technique is particularly useful for products that won't stand up to hard vacuum or that tend to spoil or change colour in low oxygen situations. Gas mixtures can be adjusted so that there's adequate carbon dioxide to inhibit the growth of microbes but also sufficient oxygen for meat to retain an appealing red colour, for example.

MAP can be used with various fresh or minimally processed foods, including meat, seafood, fruits and vegetables.

An additional piece of packaging technology which can be incorporated after removing most atmospheric oxygen using vacuum or MAP, and further extend shelf life, is an oxygen scavenger. Commonly in the form of a small sachet containing iron-based compounds and a catalyst, it removes the residual oxygen within the package.Together, we can achieve new levels of process control, efficiency, and security throughout your production, storage, and packaging processes.

Clean and pure ingredients contribute to the quality of the end product, whether it's coffee packing, potato chips, pinot grigio, or beer.

Complete Pneumatic Solutions has a dedicated range of filtration products for use in food and beverage production as well as bespoke N2 solutions to meet your needs and your pocket. The range offers wide choice, cost-saving performance and enhanced product quality.

All of our products are supported by local technical and commercial expertise, backed by the Atlas Copco global network of technical support specialists.

Food PRODUCTION industries

Coffee Production

Snacks, Chips, Crisps

Coffee is often packaged by a vertical form fill seal (vffs) machines or into PODS. Packaging coffee with air spoils the aroma and quality of the coffee. Therefore many coffee producers are using on-site on demand nitrogen generators. Nitrogen generators offer a safer, more cost effective means of supplying inert gas to the head space in bagged coffee. They replace dangerous cylinders or wasteful liquid dewars that need to changed out and ordered regularly. Businesses choose to create and control their own nitrogen supply instead of contracting with a third party gas supplier.

With many customers in Sydney already availing of our services and the benefits that come with on site N2 production, now is the time to enquire. Send us your details and we can help to look at the best most cost effective solution for you.

PARKER SOLUTION: Atlas Copco Nitrogen Generators

Snacks, Chips, Crisps

Snacks, Chips, Crisps

Manufacturers of snacks - potato chips, crackers, etc. - seek ways to improve shelf life. Improved shelf life allows manufacturers to extend their geographical reach as well as allow product to remain in stores and consumer's homes longer.

Most packagers have turned to on-site on demand nitrogen generators as an alternative to high pressure gas cylinders or liquid dewars.

High pressure gas cylinders pose a safety hazard and liquid dewars boil off and waste a lot of the nitrogen that they contain. Nitrogen generators can be installed on-site and connected to your existing house compressed air system. These generators efficiently remove the oxygen from compressed air and deliver relatively pure nitrogen to your snack filling machine for pillow packed snack packages.

They easily connect to your form fill seal packaging equipment for quick set up.

PARKER SOLUTION: Atlas Copco Nitrogen Generators

Packaged Foods

Nitrogen gas plays an essential role in many industries, with a broad range of applications ranging from packaging to fire suppression in an obviously volatile manufacturing environment. With recent technological advancements, on-site nitrogen generation equipment can now provide purity levels equal to that of liquid nitrogen, helping manufacturers lower costs without sacrificing quality or efficiency or quality.

Consumers don't want preservatives or other additives used to make these fresh foods safe and stable. N2 offers all the benefits without the risk to product quality or your customer.

Modified Atmosphere Packaging

The normal gaseous composition of air is nitrogen (N2) 78.08% (volume per volume), oxygen (O2) 20.96% and carbon dioxide (CO2) 0.03%, together with variable concentrations of water vapour and traces of inert or noble gases.

Many foods spoil rapidly in air due to moisture loss or uptake, reaction with oxygen and the growth of aerobic microorganisms. Microbial growth results in changes in texture, colour, flavour and nutritional value of the food. These changes can make food unpalatable and potentially unsafe for human consumption. Storage of foods in a modified gaseous atmosphere can maintain quality and extend product shelf life, by slowing chemical and biochemical deteriorative reactions and by slowing (potentially preventing) the growth of spoilage organisms.

Modified atmosphere packaging (MAP) is defined as ‘the packaging of a perishable product in an atmosphere which has been modified so that its composition is other than that of air’ (Hintlian and Hotchkiss, 1986). The three main gases used in modified atmosphere packaging are O2, CO2, and N2. The choice of gas or mixture of gases is very dependent upon the food product being packed.

Fresh without compromise

Unlike most food products, fresh fruits and vegetables continue to ‘breathe’ or respire after they have been harvested.

This process consumes oxygen and produces carbon dioxide and water vapour. The key to keeping these packaged products fresh for as long as possible is to reduce the respiration rate without harming the quality of the product – its taste, texture and appearance. In general, the rate of respiration can be reduced by keeping the temperature low, having lower levels of oxygen in the packaging atmosphere and increased levels of carbon dioxide. However, things are not straightforward. For example if there is too little oxygen in the packaging atmosphere, a process called anaerobic respiration will kick in. This produces unwanted tastes and odours in the product and will cause the food to deteriorate. Furthermore, excessively high carbon dioxide can damage some varieties of product. As well as these considerations, the high water content of this class of food, plus the fact that fruit are intrinsically acidic, can lead to spoilage from yeasts and mould. Also, the flesh can become soft because of attack by enzymes from microbes, eventually resulting in rotting. The packaging material used for fruit and vegetables is especially crucial and in particular how permeable or breathable the material is. If the products are sealed in an airtight package, oxygen will soon become depleted and undesirable anaerobic conditions could develop. On the other hand if the material is too porous, the modified atmosphere will escape and no benefit will be derived.

Have you eaten products with CPS N2?

Yes is likely the answer if you have every eaten Maccas, Subway, KFC, Coffee POD, Pre packed salad from Aldi, Woolies or Coles & many more.

Using nitrogen gas in food packaging is one of the main methods of food preservation because it is a way to displace oxygen. Oxygen is the main culprit in the air that causes spoilage.

Oxygen is a powerful oxidizing agent and produces spoilage by reacting with compounds like fat and sugars. For example, you may have noticed the browning of an apple after it has been bitten. This is due to oxidation taking place. This natural process causes damage to food creating unpleasant odors and spoilage.

Also, some forms of bacteria use oxygen to grow. If oxygen is made available, the bacteria will thrive on food. This could lead to a potentially dangerous growth of harmful bacteria that will increase the rate of spoilage. In fact, not only would the bacteria spoil the food, but they could also cause disease and/or death in people who consume that food.

Additional Information

Nitrogen gas plays an essential role in many industries, with a broad range of applications ranging from packaging to fire suppression in an obviously volatile manufacturing environment. With recent technological advancements, on-site nitrogen generation equipment can now provide purity levels equal to that of liquid nitrogen, helping manufacturers lower costs without sacrificing quality or efficiency or quality.

Modified atmosphere packaging

Modified atmosphere packaging (MAP) is food packaging in which the composition of the air surrounding the food in the package is changed. The main gases used in MAP are oxygen, carbon dioxide or the inert gas, nitrogen.

The MAP technique is particularly useful for products that won't stand up to hard vacuum or that tend to spoil or change colour in low oxygen situations. Gas mixtures can be adjusted so that there's adequate carbon dioxide to inhibit the growth of microbes but also sufficient oxygen for meat to retain an appealing red colour, for example.

MAP can be used with various fresh or minimally processed foods, including meat, seafood, fruits and vegetables.

An additional piece of packaging technology which can be incorporated after removing most atmospheric oxygen using vacuum or MAP, and further extend shelf life, is an oxygen scavenger. Commonly in the form of a small sachet containing iron-based compounds and a catalyst, it removes the residual oxygen within the package.

Modified atmosphere is the practice of modifying the composition of the internal atmosphere of a package (commonly food packages, drugs, etc.) in order to improve the shelf life.[1]The need for this technology for food arises from the short shelf life of food products such as meat, fish, poultry, and dairy in the presence of oxygen. In food, oxygen is readily available for lipid oxidation reactions. Oxygen also helps maintain high respiration rates of fresh produce, which contribute to shortened shelf life.[2] From a microbiological aspect, oxygen encourages the growth of aerobic spoilage microorganisms.[1] Therefore, the reduction of oxygen and its replacement with other gases can reduce or delay oxidation reactions and microbiological spoilage. Oxygen scavengers may also be used to reduce browning due to lipid oxidation by halting the auto-oxidative chemical process.

The modification process generally lowers the amount of oxygen (O2) in the headspace of the package. Oxygen can be replaced with nitrogen (N2), a comparatively inert gas, or carbon dioxide (CO2).[1]

A stable atmosphere of gases inside the packaging can be achieved using active techniques, such as gas flushing and compensated vacuum, or passively by designing “breathable” films.

Modified Atmosphere Packaging - A fresh approach to food packaging

Modified Atmosphere Packaging is also known as gas flushing, protective atmosphere packaging or reduced oxygen packaging.

Modified Atmosphere enables fresh and minimally processed packaged food products to maintain visual, textural and nutritional appeal. The controlled MAP environment enables food packaging to provide an extended shelf life without requiring the addition of chemical preservatives or stabilisers. Processors and marketers of food products rely on Modified Atmosphere Packaging to assure fresh and flavourful products that continually meet the consumer’s expectation for brand quality, consistency, freshness and in-stock availability.

What is Modified Atmosphere Packaging?

Modified Atmosphere Packaging is an optimal blend of pure oxygen, carbon dioxide and nitrogen within a high barrier or permeable package. A finely adjusted and carefully controlled gas blend is developed to meet the specific respiration needs for each packaged food product.

Plastic films, foils and other packaging materials that demonstrate specified gas permeability properties and/or water vapour permeability properties are selected for use. These high barrier substrates become MAP Packages after they are formed into trays, lid stock or bags and filled with a select blend of oxygen, carbon dioxide and nitrogen environmental gasses.

Packaging films are selected to match the characteristics and needs of the food product. Film permeability, water vapour transmission rates and sealing characteristics need to be measured and tested at film selection and again at package converting and product fill stages, since the ability of a film to handle MAP performance characteristics may vary within each stage.

CPS Compressors Australia

Air Compressor Sales, Service of all brands, Spare Parts, 24/7 Breakdown - Unit 28, 20 Tucks Road, Seven Hills, Sydney, NSW 2147, Australia

Copyright © 2025 CPS Compressors - All Rights Reserved. Authorised DENAIR Distributors

Part of the CPS Group of companies, Australia